Our other sites

© Sandvik Mining 2012

Tel +46 (0)26 260000

info.mining@sandvik.com

Loading site...

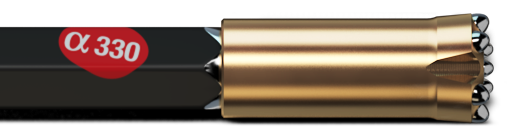

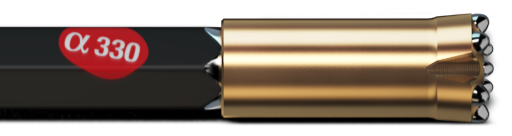

Today’s rock drills generate almost unlimited impact power. We need to control that power and, most importantly, ensure that it is transmitted into the rock as efficiently, accurately and economically possible. That is the job of the rock drilling tools, which is why we continue to develop the Sandvik Alpha 330 tool system – to bring the best solution for performance and productivity.

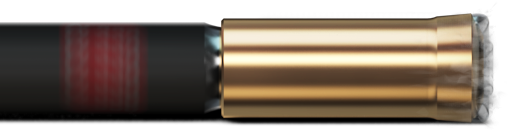

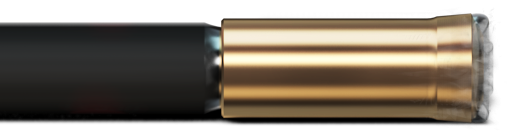

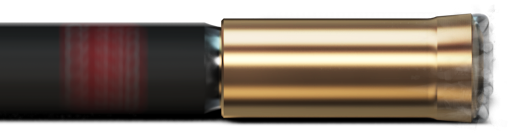

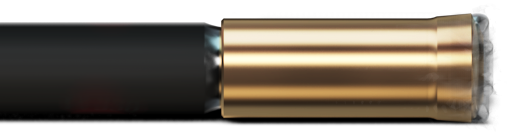

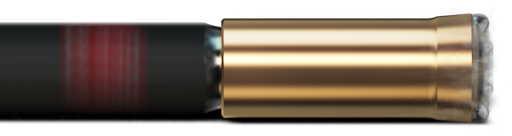

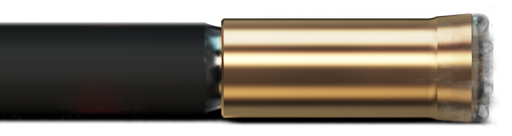

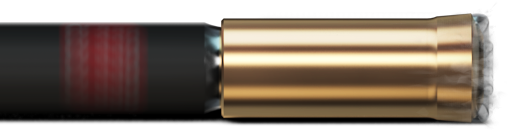

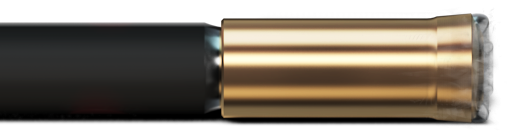

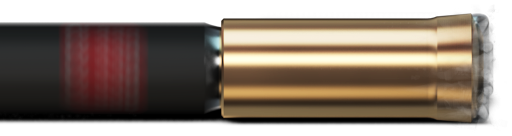

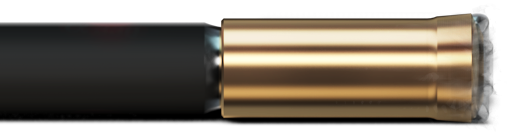

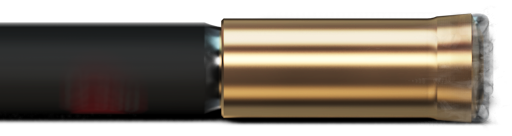

The drill string rod/bit connection features an entirely new thread design and the rod itself is of the well-proven Hex 35 section, with a T38 thread at the shank end.

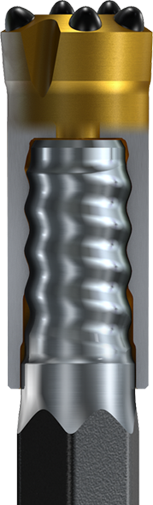

The new short thread design on the hexagonal rods in the tool system result in a rigid, integrated powerpack drill string with superior resistance to bending stresses, improved bit guidance and perfect energy transfer. The sturdy thread is well guided inside the bit skirt, offering high precision in collaring – even in complex rock formations and against uneven surfaces.

A snug interface at this crucial point at the rear of the connection greatly improves the rigidity of the joint. The bit skirt covers the thread completely in the Sandvik Alpha 330 connection, no part of the thread itself is exposed to sandblasting, reducing the risk of corrosion-fatigue.

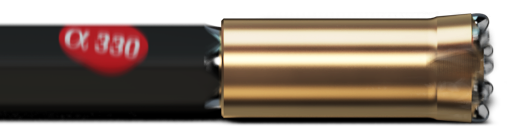

To match the increased energy output from modern high-power rock drills in drifting

and bolting, the new Sandvik Alpha 330 has been designed and dimensionally optimized to replace R32 connections (also a Sandvik innovation) which has been

the dominant Ø 45 mm system todate.

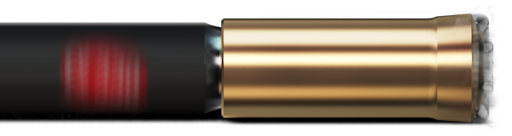

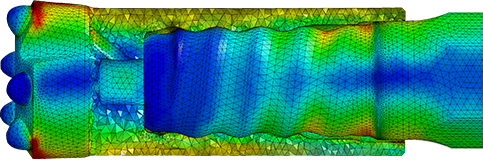

Using advanced FEM programs we are able to simulate the application of our designs long before the solution touches the rock.

Advanced analysis has been used to simulate and locate critical bending stresses of various designs to arrive at an optimally dimensioned rod/bit connection.

Thread length & diameter means at least 30% better service life on drifter rods when compared to R32. More steel for higher fatigue strength makes the connection rigid compared to the R32, to give exact collaring and straighter holes.

lower cost for drilling tools

After using the Sandvik Alpha 330 tool system, customers in both mining and tunneling applications all over the world have identified the following advantages:

New Short thread design and hexagonal rods result in a rigid, integrated drill string optimized for 43 to 51 mm drilling.

The new short thread design offers increased precision in collaring.

The rigid drill string results in straighter holes, permitting optimum drilling patterns, better hole accuracy and higher rates of advance.

Exact collaring and straighter holes are prerequistes for productive drilling with less over break and lower overall costs.

Less downtime of machinery resulting in better scheduling through optimal productivity.

With the Sandvik Alpha 330 you just drilled a straighter hole than if using the R32.